Thermal desorption and pyrolysis of the same sample can be performed in sequence, allowing the analyst to get the most amount of information in the shortest possible time.

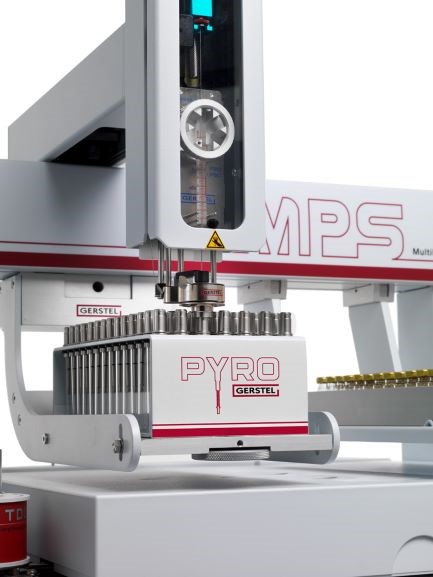

Automated Pyrolysis GERSTEL PYRO

The GERSTEL PYRO enables highly flexible and efficient automated pyrolysis of solids and liquids at up to 1000 °C combined with determination in a GC/MS system of the thermal decomposition products. If required, thermal desorption and pyrolysis of the same sample can be performed in sequence, enabling the analyst to obtain the cleanest possible pyrogram and the maximum amount of information in the shortest possible time. Some key areas in which the PYRO is used are production quality control; product development; and forensic science.

Features and Benefits

- Multiple pyrolysis techniques available

- pulsed pyrolysis

- sequential pyrolysis

- fractionated pyrolysis

- Thermal desorption with solvent venting and pyrolysis of the same sample

- Split- or splitless operation

- Selectable cryo trapping

- Efficient and reliable automation

- Dedicated optimized sample holders for liquid and solid samples

- Flexible and proven resistance heating using Pt filament provides selectable pyrolysis temperature from 350 – 1000 °C

- Liner in liner system / No valve in sample flow path

- Flexible modular system

- Integrated MAESTRO software control