CHALLENGE

With the large number of analyzers and analytical techniques available on the market, petroleum laboratories face the challenge of choosing the optimal approach to ensure high-quality data. X-ray fluorescence (XRF) is a technique recognized for its ease of use, requiring no injections, sample consumption, or combustion. In the field of elemental analysis, XRF is considered to require less intensive training for technicians.

However, sample preparation for XRF still relies on the operators' ability to perform sample preparation correctly and enter data without error to ensure the reliability of laboratory results. This article details known best practices for sample preparation with an XOS Sindie +Cl analyzer. Topics covered include cleanliness, measurement time, ventilation, repeated measurements, and calibration, among others. This article thus presents the repeatability of measurements on the Sindie +Cl by applying appropriate sample preparation techniques and guides users to ensure the highest possible quality of analytical data.

BEST PRACTICES

Cleanliness

A clean sample preparation area is essential to avoid cross-contamination between samples. For example, an XRF dish in contact with a pipette that has contained a different type of sample could compromise data integrity. For optimal results, follow these precautions:

- Store all materials, such as XRF dishes and pipettes, in closed containers rather than open ones

- Perform sample preparation in a ventilated fume hood

- Keep the sample film box closed when not in use.

To avoid

In addition to cleaning the sample preparation area, it is especially important to keep the analyzer clean. When multiple samples are analyzed, occasional leaks can accumulate and compromise the data integrity and repeatability of sulfur analyses. To avoid these risks, perform the following tasks daily to ensure your XRF analyzer is not a source of errors:

Clean the plunger and sample basket with isopropyl alcohol (IPA) and a lint-free cloth.

Thoroughly clean the primary window with IPA and a foam-tipped swab (make sure you have a spare primary window before instituting a regular cleaning procedure).

Important!

It's important to note that the proper technique for cleaning this area involves first shaking off the excess alcohol from the swab. Then, hold the swab parallel to the analyzer surface (rather than perpendicular) and gently wipe it over the primary window film. This will reduce the likelihood of breaking the window. Alternatively, use a foam makeup sponge or a lint-free cloth to clean the primary window. Use canned or clean compressed air to dry the window. Do not shake the can of compressed air before use, as this may leave residue on the primary window. If this happens, repeat the cleaning procedure.

Another precaution to take is when changing the secondary window. When changing the secondary window, it is important to use canned or clean compressed air on the sample film to remove any contaminants. Wear gloves and avoid touching the film when installing it. Using four fingers, apply even pressure at equidistant points around the perimeter of the retaining ring to secure the window and ensure there are no wrinkles in the film. If the secondary film has wrinkles, repeat the procedure.

Whether cleaning the sample preparation area or preparing a sample, you must ALWAYS wear disposable gloves.

SAMPLE PREPARATION

Proper sample preparation is arguably the most crucial element in improving the repeatability of sulfur analyses. Improper sample preparation or contamination are the main causes of repeatability issues. Start with a clean sample preparation area and make sure you have all the necessary supplies on hand.

The steps:

Use canned or clean compressed air to blow out any contaminants into a new sample cup. Do not reuse disposable cups. Shake the sample bottle to ensure homogeneity and use a new, disposable pipette to fill the cup. Fill the cup at least halfway, more for viscous samples. Spray compressed air onto a piece of sample film before placing it on top of the full cup. The type of film depends on the analyzer being used – follow the manufacturer's recommendations. Using four fingers spaced evenly around the neck of the cup, press evenly to secure the film and lock the assembly. Visually inspect for wrinkles in the film, as these can negatively affect data quality.

Finally, turn the sample face down on a support or lint-free wipe. Never place a cup face down on a work surface. Use a clean pushpin to vent the sample, avoiding the center of cells with a central well, which increases the risk of leakage. On a monochromatic X-ray fluorescence (MWDXRF) analyzer, it is essential to vent all samples (not just volatile samples) to ensure a flat film surface when the analyzer lid is closed.

Please note:

If the analyzer uses XOS Accucells, the previous cup assembly steps are not necessary. With Accucells, simply pipette 1 ml of sample to fill the pre-assembled, pre-vented cup. For labs looking to minimize risks associated with improper preparation, consider the Sindie Gen3 analyzer, which uses Accucell cups.

REPEATABILITY OF MEASUREMENTS AND MEASUREMENT TIME

Although many analyzers, including the Sindie +Cl, have software that allows for repeat measurements, it is recommended that users prepare separate aliquots for each measurement. Repeat measurements increase the risk of sample evaporation or film wrinkling over time, which can affect data quality and the repeatability of sulfur analyses. Furthermore, to comply with ASTM D2622, repeat measurements are required for samples containing ≤100 ppm sulfur, and each determination must be performed on a new sample portion (D2622 Section 10.12).

It is also recommended to prepare samples as needed. Preparing multiple samples in advance on a single-cell analyzer, rather than waiting for the measurement to be completed before moving on to the next sample, can introduce a contamination risk.

Finally, follow the recommended measurement time. For best results, measure low concentration samples ≥1 ppm for 300 seconds and samples ≤1 ppm for 600 seconds on Sindie, Sindie +Cl, and Clora. In general, for stable, non-volatile samples, the longer the measurement time, the higher the number of counts, and the better the measurement accuracy.

Once the measurement is complete, remove the sample as soon as possible. Leaving it in place may increase the risk of sample leakage into the measurement chamber.

MAINTENANCE AND CALIBRATION

Maintenance

Although routine maintenance for XRF analyzers, such as the Sindie +Cl, is minimal compared to other analytical equipment, it is still essential to incorporate regular analyzer checks. The analyzer must be kept in optimal condition to avoid major problems. A simple step is to regularly check the fan filter at the rear of the analyzer and clean it as needed. This will help prevent dust buildup, which could increase the risk of overheating the air-cooled X-ray tubes.

Many laboratories have integrated statistical quality control (SQC) into their processes. The frequency of these checks is often determined by regulatory tests (e.g., US EPA Tier 3 gasoline) or ASTM methodology recommendations. Regular SQC checks will signal when the analyzer is not in statistical control and reduce the risk of performing product measurements during this time. If the SQC graph is not in statistical control, it is important to investigate the cause and recalibrate the instrument if necessary.

Calibration

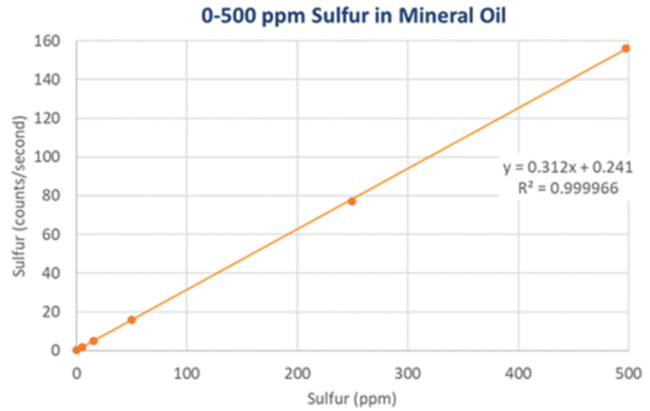

Calibration should be performed after any major analyzer modification or maintenance, such as an X-ray beam replacement. When calibrating MWDXRF analyzers, it is not recommended to limit the calibration range too narrowly. To measure sulfur in the sub-10 ppm range for gasoline samples, it is recommended to calibrate from 0 to 500 ppm. This approach is recommended because Sindie analyzers use a weighted, extremely linear calibration (as shown in Figure 1), and the high points anchor the calibration slope, thus reducing the standard error of the calibration intercept.

Weighted calibration of Sindie +Cl

Weighted calibration of Sindie +ClFinally, the use of matrix matching or correction factors for gasoline samples can improve measurement accuracy by reducing or eliminating bias. Gasoline exhibits a slight upward bias (approximately 1%) when measured with a mineral oil calibration. Gasoline containing ethanol exhibits a downward bias on the same mineral oil calibration, due to matrix effects caused by oxygen in the sample. Correction factors for gasoline and oxygenated gasoline blends measured on a mineral oil calibration can be found in Table 3 of the D7039 standard. It should be noted that these correction factors are also applicable to Sindie analyzers in 2622 mode, as the basic geometry of the Sindie analyzer does not change when it is in 2622 mode.

DATA QUALITY

To demonstrate the impact of proper sample preparation, measurements were performed on a Sindie +Cl analyzer. The prepared samples were from commercial diesel and gasoline standards. The known concentration values for these samples were 10 ppm for diesel and 9 ppm for gasoline. Following the good practices mentioned above, we performed 10 measurements and calculated the mean, standard deviation, and relative standard deviation of the measurement data, as shown in Table 1. The result shows a low relative standard deviation, less than 5%, which demonstrates excellent consistency and very good repeatability of the sulfur analyses performed with the analyzer.

Table 1: Traces of sulfur (ppm) in fuels

| Diesel | Essence

|

| Evidence | Results | Results |

| 1 | 9.5

| 8.88 |

| 2 | 9.49 | 8.15 |

| 3 | 9.53 | 7.79 |

| 4 | 9.26 | 8.64 |

| 5 | 9.75 | 8.51 |

| 6 | 9.00 | 8.86 |

| 7 | 9.82 | 8.48 |

| 8 | 9.03 | 9.17 |

| 9 | 10.49 | 8.83 |

| 10 | 9.89 | 8.88 |

| Medium | 9.59 | 8.62 |

| Standard deviation | 0.443 | 0.405 |

Coefficient of variation

(%) | 4.62% | 4.71% |

CONCLUSION

XRF analyzers, like Sindie +Cl, offer oil professionals a simplified method for taking blood measurements without requiring exhaustive échantillon preparation. In addition to these good practices, operators can reduce the risks of compromising women and saving money by optimizing their production process.

Would you like to know?

Do you know the difference between Reproducibility (R) and Reproduction (R)?

Reproducibility (R) = between two laboratories

Reproductibility (R) is the difference between two independent results obtained by different operators, applying the same test method in different laboratories, using different devices on an identical test material. In this case, in the long term and in normal and correct conditions of operation of the test method, the calculated value should be calculated at 20 times (5% of times).

Thus, the reproducibility is the maximum expected difference (at a level of confidence of 95%) within two measurements taken on the same material using the same test method for two different laboratories, each using a different apparatus and operator.

The Repetition (r) = from the same laboratory

The Repetition (r) is defined as the difference between the repeated results obtained by the same operator in a female laboratory, applying the same test method with the same apparatus, sous constant exploitation conditions, on an identical test material and in court time intervals. In this case, in the long term and in normal and correct conditions of operation of the test method, the calculated value will be exceeded at 20 times (5% of times).

Or, more simply, the reliability is the maximum difference expected (at a level of confidence of 95%) between two results of measurements effectuées on the same material, using the same device, the same test method and the same operator.