Clora®, Clora 2XP® e Sindie+Cl®

The new Clora® R series benchtop analyzers are easy to use, allow you to carry out rapid tests and allow you to work in compliance with method directives in a flexible, accurate and precise way.

Based on MWDXRF technology, these analyzers provide direct measurements and require no gas consumption or sample handling.

New Clora® R series

Clora® measures total chlorine in hydrocarbons such as aromatics, distillates, heavy fuels, crude oils, and water. This state-of-the-art technology complies with ASTM D7536 and D4929C and delivers unparalleled accuracy and precision for petroleum and petrochemical applications where simple, quick, and reliable analysis is critical.

APPLICATIONS

- Total chlorine analysis in petroleum products, biofuels, aromatics and other chemicals, and water

- For refineries, petrochemical and additive plants, pipeline terminals, and test laboratories

FEATURES AND BENEFITS

- LOD: 0.13 mg/kg (ppm) at 300s, 0.09 mg/kg (ppm) at 600s for hydrocarbons, 0.3 mg/kg (ppm) at 300s, 0.21 mg/kg (ppm) at 600s for aqueous samples

- Dynamic range: 0.13 mg/kg (ppm) to 4 wt%

- Manual sulfur correction to correct for high sulfur samples

- Low and high range calibrations available:

– Low range: 0.13 mg/kg (ppm) – 3000 mg/kg (ppm)

– High range: 0.3 wt% – 4 wt%

New Clora® 2XP R series

Easier to use than ever, Clora® 2XP analyzes total chlorine in liquid hydrocarbons such as aromatics, distillates, heavy fuels, and crude oils, as well as aqueous solutions, while automatically correcting for sulfur interference.

The enhanced precision and performance technology makes it the ideal choice for testing related to catalyst poisoning in reformers or for sites with fluid catalytic crackers and hydrocrackers monitoring very low chlorine levels. This state-of-the-art technology complies with ASTM D7536 and D4929C.

APPLICATIONS

- Total chlorine analysis from aqueous solutions and aromatic products to heavy fuels and crudes

- For refineries, petrochemical and additive plants, pipeline terminals, and test laboratories

FEATURES AND BENEFITS

- LOD: 0.1 mg/kg (ppm) at 300s, 0.07 ppm at 600s in

hydrocarbons** - Dynamic range: 0.1 mg/kg (ppm) – 2 wt%

- Automatic sulfur correction saves time and improves accuracy and precision on high sulfur samples

- Low and high range available:

– Low range: 0.1 mg/kg (ppm) – 3000 mg/kg (ppm)

– High range: 0.3 wt% – 2 wt%

All new Clora R series analyzers are:

- Easy to use:

– Intuitive 10-inch touch screen

– Just plug in and measure

– Measurement time: 10-999 s - Low maintenance: no gasses, heating elements, columns, or quartz tubing

- Traditional XRF sample cups or XOS Accucells

- Small footprint

- LIMS integration for data management and transfer

- Preset favorites capability to save data entry time and minimize mistakes on common samples

- Bar code reader autofills sample name to reduce data entry time

- Storage capacity for more than 50,000 measurment results

- Supports up to 30 calibration curves

- USB connectivity in front and back for connecting toprinter, keyboard, mouse, memory stick

- Supports USB as well as network printers

- Large, easy-to-remove side panels for easy serviceability

- Advanced error reporting and diagnostics

Sindie+Cl – TWO critical measurements, ONE push of a button, ZERO hassle

Sindie +Cl is a sulfur and chlorine analyzer delivering two critical measurements with one push of a button and zero hassle. It is the ideal solution for refineries and independent labs to certify sulfur levels in finished products and assess chlorine for corrosion mitigation, all with one instrument. Sindie +Cl utilizes a technique known as Monochromatic Wavelength Dispersive X-Ray Fluorescence (MWDXRF) – delivering exceptional reproducibility. Samples are measured directly, which means it can analyze even the heaviest of hydrocarbons like crude oil or coker residuals without the hassles of boats, injectors, furnaces, or changing detectors. This model utilizes standard XRF sample cups.

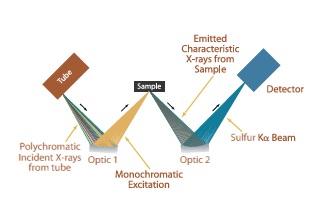

MWD XRF Monochromatic Wavelength Dispersive X-Ray Fluorescence (MWD XRF) utilizes state-of-theart focusing and monochromating optics to increase excitation intensity and dramatically improve signal-to-background over high power traditional WD XRF instruments.

This enables significantly improved detection limits and precision and a reduced sensitivity to matrix effects. A monochromatic and focused primary beam excites the sample and secondary characteristic fluorescence x-rays are emitted from the sample. A second monochromating optic selects the sulfur characteristic x-rays and directs these x-rays to the detector. MWD XRF is a direct measurement technique and does not require consumable gasses or sample conversion.

Brochure

Data Sheet

Detailed How to Measure Chlorides in Crude Oil by ASTM D4929C & Water Extraction

ASTM D4929C Gaining Traction

Rapid and Accurate Analysis of Sulphur and Chlorine in Biofuels by XRF

With the continued development of biofuels and a push for higher concentrations in traditional fuels, petroleum professionals are looking to utilize technology that delivers rapid and accurate results for on-site biofuel measurement. Sindie +Cl is a viable solution, delivering total sulphur and chlorine in one measurement without the need for a matrix-matched calibration by simply applying a correction factor to the results. This allows professionals to certify their biofuel products more efficiently than with other methods. Sindie +Cl complies with ASTM D2622, and therefore meets the regulatory limit of ASTM D6751 and ASTM D7467. It also meets the precision requirements for ISO 20884 and can be used for EN 14214.

A Comparison of Chlorine Levels in Aromatics Using MWDXRF and Microcoulometry

When measuring aromatics, precision and accuracy at low concentrations are critical. From the ASTM data shown, MWDXRF analyzers, particularly Clora, demonstrate excellent accuracy when measuring samples against microcoulometry. The ability to measure total chlorines with minimal sample preparation and high performance, with results ready within minutes, is invaluable to refiners looking to protect their bottom line – and for these specific needs, Clora delivers on all fronts.